How Automated Bluetooth and Wi-Fi Interoperability Testing Mitigates Risk For Product Teams

In an increasingly connected world, launching tech products without first completing extensive Bluetooth and Wi-Fi interoperability testing is a major risk.

Automated Bluetooth and Wi-Fi interoperability testing won’t take away every pressure you face as a product owner - but it will alleviate most by answering some of your most pressing concerns:

-

Is the user experience on your latest product up to scratch?

-

Are you confident you have successfully validated the product’s quality before it goes to market?

-

Have you reduced or eliminated - to as great an extent as is practically possible - the number of defects your product contains?

-

And have you been able to produce detailed root cause analyses of any inherent defects, enabling you to solve them before major reputational impacts begin to affect your company’s financial performance?

Here are several ways automation can strengthen your testing process, secure the support of key stakeholders across your business, and reduce the threat of going to market too soon.

1. Extensive and Dynamic Testing

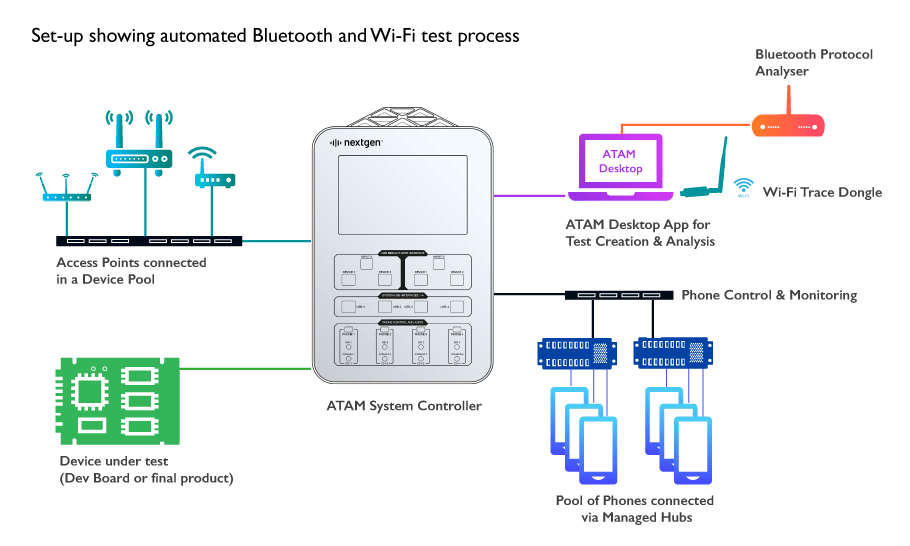

Automated Bluetooth and Wi-Fi interoperability testing can accurately conduct tests with far greater depth than manual test processes are likely to achieve.

When your product is designed to meet a range of complex use cases, checking every case is crucial. Automation enables a broader range of test cases and can test them at speed. It means testing scenarios where multiple functions are simultaneously at use become not only possible but foundational to your testing strategy.

Automation can also test features dynamically, such as testing battery-powered devices over a stretch of time to accurately assess the impact of depleting power reserves on product performance.

2. Issue Identification

Issue identification and accountability are key strengths of automated interoperability testing. An automated testing platform can identify deeply hidden bugs that may otherwise be missed by humans, pinpoint precisely where an issue lies, and deliver detailed bug reporting.

Detailed logs, traces and bug reports created by automated testing enables reproducibility, quicker resolutions and faster go-to-market times

3. Less Pressure

No longer does your team have to expand (at significant cost) or work long, draining hours when you are in the final stages of product development. With automated interoperability testing, the strain is relieved on test engineering and QA teams.

So your colleagues are able to perform at higher levels on issues such as testing strategies, analyses and bug resolutions, while automation handles the nuts-and-bolts of completing the actual tests.

4. 24/7 Operations

Manual testing has its merits and is an appropriate choice in several situations. But what manual testing cannot do is operate when test engineers are not at work.

Once set up, automated Bluetooth and Wi-Fi interoperability testing can - in contrast - work through a sequence of tests regardless of whether QA or engineering staff are present.

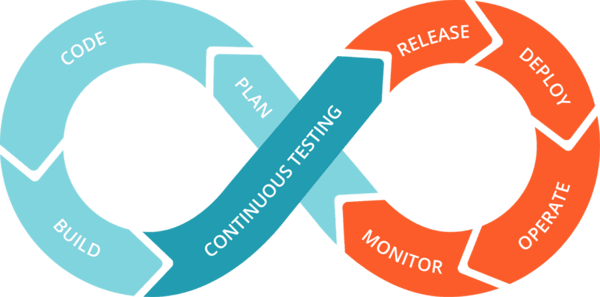

Testing operations can proceed on a 24/7 basis, as part of a continuous integration, continuous development (CI/CD) framework. When engineering staff are ready, the test results, logs, traces and more are available for analysis and action.

5. Lower Cost-per-Test

Automated testing comes with an initial set-up cost. Investment in the testing platform, training and setup can mean automation is - in the early stages at least - more costly than manual testing.

But as time goes on, the ongoing costs needed to conduct automated testing begin to fade as the economies of testing at scale increase. Meanwhile, the costs and resources of running manual tests remain relatively consistent and linear: time is money, and manual testing demands the same test resource each time.

6. Inherent Scalability

Linked to automation’s lower costs-per-test is the fact that automated interoperability testing is inherently scalable. It provides manufacturers with the ability to increase test capacity without a proportional increase in HR costs.

It also enables manufacturers to rapidly increase the number of tests being conducted as products go through the development and QA process. So while HR costs are lowered, flexibility in the scale of testing achievable is not compromised.

7. Easy comparisons

Automated testing is far less open to human error than manual testing. Each test is tightly defined by QA or engineering teams, then programmed into the platform to be executed as many times as required without any process drift or unplanned variation.

As a result, data is consistent, meaning tests completed at different times - or in different locations - can be confidently merged, compared and analysed together.

Make Automated Interoperability Testing Part of Your Future

Depending on your circumstances and objectives, arguments can be made for both manual and automated Bluetooth and Wi-Fi interoperability testing. But only automated testing will give you the scale, depth and complexity of testing you need to robustly test all aspects of a product and go to market with confidence.

To find out more about how we can help you create better connected products that maintain and strengthen your company’s performance, profitability and reputation, contact us today.